An exhaust under a car has three functions:

* Removal of combustion gases.

* Dissipating the heat produced by the engine.

* Mute sound

Exhaust gases leave the engine under high pressure and expand enormously immediately after leaving the combustion chambers. The explosion of the gas mixture and the expansion of the exhaust gases leaving the block create the noise, the sound or the 'sound'. The most common intention is to reduce this noise to something that children and dogs do not flee from.

Types of sound

* The sound from the exhaust ports to the first muffler.

* The sound from the dampers, the so-called break-out sound.

* The noise coming from the end of the exhaust system.

* The sound transmitted to the body by the exhaust suspension points

Types of dampers

Three ways are used to dampen the sound in the exhaust: the vane principle, the absorption principle or a combination of the two. The fact that almost all car manufacturers opt for an exhaust according to the bulkhead principle has two reasons: The manufacturing costs are low and the noise reduction is quite good.

But there are some drawbacks to the partition system. It stands in the way of an optimally fast discharge of exhaust gas so that the back pressure can become (too) high. The resulting build-up of heat inside the mufflers will also increase the temperature of the engine and, in the worst case, could lead to cherry red exhaust bends and burnt exhaust valves. In addition, poor gas evacuation impedes the engine's exhalation so that the engine is throttled. Think of the joke with the potato in the exhaust pipe. Clearly better are dampers that work according to the absorption principle, the dampers that are sold under the nickname 'sports dampers'.

You can best imagine these mufflers as a thick pipe through which the exhaust gases are discharged directly. The pipe is perforated at the level of the damping part and provided with soft and heat-resistant damping material all around. The exhaust gases can thus continue their way without hindrance while there is indeed damping because the sound, the vibrations in the air, are absorbed by the damping material.

A good absorption damper hardly needs to make more noise than a bulkhead damper, at most that sound is of a deeper sound. The bad reputation comes from cheap absorption exhausts that produce a lot of noise. In addition, it is not only China where less good stuff comes from. From the USA we know the Cherry Bombs, thin long absorption dampers with little absorption material. This results in a fierce and blaring exhaust note. (Among connoisseurs this sound is also called 'the sound of people without money'.)

With a good absorption exhaust you will not get into a fight with the neighbors and - with a possibly adjusted nozzle occupation - 5-15% more power can be extracted from a block. In addition to more power, the gain is also in a higher torque (pulling power).

RVS

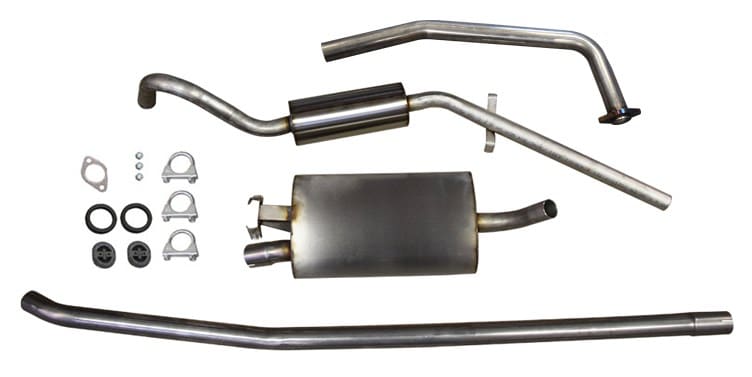

The most durable material used in the (sports) exhaust industry is stainless steel. Two types of stainless steel are used: AISI 409 and 304. 409 Is more flexible and very heat resistant. It will show surface corrosion. 304 is a bit harder but will not rust (almost). Therefore, 409 is well suited for the exhaust front pipe and 304 for the rest including the mufflers.

With a good, well-made stainless steel system, the exhaust can be guaranteed for life. However, beware: there are also big differences here. An example of how it should not be damper inserts that are not made of stainless steel, or the use of only fiberglass as absorption material, so that sooner or later the dampers 'blow empty'.

There are a few companies in the Netherlands that have a very good reputation in the field of exhausts, where EPS makes many of the eyes of American V8 enthusiasts shine.

What Ilco mentions about the lubrication of stainless steel bolts and nuts is indeed the holy grail of preserving the bolts. With ceramic paste you prevent the notorious stiffness.

And from the time of my old tuned Golf D I know how important the good suspension of an exhaust system is. Good suspension is the preservation of the system. After I had put so-called 'Sportrubbers' underneath, the exhaust no longer broke off or or otherwise didn't hit the body anymore because of the crazy cornering speeds that we used to keep. Swallow… ..😬

The current stainless steel exhaust material is fine and guarantees carefree operation for many years to come.

A common mistake is the wrong suspension material. Wrong brackets, wrong bolts. When mounting stainless steel bolts ALWAYS use suitable grease, otherwise damage will occur in the screw thread and the bolt and nut will be irretrievably lost.

It remains difficult to find the right damping for rare old timers. Of course, this does not only apply to stainless steel exhausts.

In the past, the price of stainless steel compared to ordinary carbon steel was simply very high. That alone was reason enough to make exhausts out of steel. In addition, austenitic stainless steel types, depending on the composition, suffer to a greater or lesser extent from stress corrosion cracking when chlorides are deposited on them (say road salt) at higher temperatures. That is also a limitation. Better (de) formable stainless steel types were not yet timeless. When shaping, some types often suffer from deformation hardening, after which you have to give the workpiece (depending on what you are making with it) an interim heat treatment before further shaping. At least, you want to avoid tearing or breaking. Nowadays it is all a lot better and the truly beautiful exhaust systems are made in stainless steel. And all that beauty seems to have sprung from the so-called 'V2A' steel from Krupp.

Around WWII 'Versuch 2A' produced a stainless steel variant. Not that the rusting was the problem now because before the armor of a tank was rusted through, you had been a century on, it turns out. An anti-tank grenade, which burned a hole in the armor of a tank with oxygen, suddenly found its way in much more difficult. That turned out to be invaluable.

I have a Simons exhaust under my Amazon, the rear silencer I made myself with stainless steel filling sounds better than original.

John Gers

In the past exhausts gave up the ghost faster than it seems today.

The 1985 Nissan Sunny was turned every 5 years.

Who still suffers from a rotten exhaust in modern cars? ?

But in the past it could also be better.

My Audi 200 from 1986, I mounted a stainless steel exhaust underneath in 2013 or something, sportier pipe.

But the original was still pretty good after just 3 tons.

Welds got worse.

Steel, non-stainless steel exhausts can also be good.

My original exhaust lasted 20 years and 2 months (or 365.000 miles) before it broke in 2 pieces with rust.

The aftermarket that was set up after it broke into two pieces after 5 years.

Quality of the steel and thickness of the steel also play a role in its lifespan.