“Doctor, I have broken leaf springs!

What should I do? Am I throwing the car away? Do I replace the entire package or just the magazine in question? "

Find a leaf feather donor

On a car after 1950 the answer will be clear: A set of leaf springs “borrowed” from a donor car of the same model can be a good remedy, provided that these blades are not too loose and have not lost their elasticity, or to make it correct to express: have retained their curvature.

If, unfortunately, they do not meet this requirement, it is worth considering re-tensioning them. To this end, the leaf spring or springs must be heated to ± 450ºC.

'Boiling up' is a long way

This treatment is called 'freshening up' or, in English, re-arching. The incorrect term 'boiling up' is also used. The curve is then restored with a hammer and anvil. "The steel remembers its initial form". The heating of the metal brings this memory to life. Fire as a remedy for memory loss. This approach is certainly not to be confused with the 'cold' tensioning of the spring by means of all kinds of stuffing and tensioning. That is patchwork.

But sometimes a problem is a bit more complicated

For example, with really old cars. See just to find a set of leaf springs for this. And if the main sheet is broken, then what? There is also an answer, but first some explanation. Leaf suspension - except for more modern American cars - does not consist of one leaf, but of several blades. Each of these blades reacts with the blade below and above to ensure good progressiveness to the spring characteristic.

So avoid too great a load

Excessive load can cause deformation. This can be checked with a curved strip of tin as an example: Support the ends. When a weight is put in the middle, the strip of tin will bend. If the weight is too great, it will 'burst'. If a second blade is imposed that is a little shorter to account for the bend of the first blade, and if the two blades are held together, the bending will decrease at the same weight.

The more blades are added, the clearer the effect will be. This also applies to shocks. If a single piece of iron is struck, it will vibrate for a very long time; the pendulum movement of relaxation and compression. When one or more blades are stacked, this vibration effect will be noticeably reduced.

That is why leaf springs should never be greased. They will slide relative to each other. They need a minimum of grip to respond with each other. The friction that occurs between the blades during bending has a self-damping effect.

Leaf springs: never grease

A leaf spring can be painted, diesel fuel can be sprayed on it to dislodge the superficial rust, but greasing is taboo. Good, but now it has not been told what a main magazine is. That is very simple: the first leaf, that which ensures the connection to the chassis by means of forged loops. All other springs are numbered: 2, 3, 4, 5, 6, ... This spring package is connected crosswise at the lowest point (often offset from the center). This makes the leaf springs in line. The spring blades are connected to each other by a spring or tower bolt. Shifting sideways is prevented by clamps.

"And doctor, what can you do for my broken leaf spring?"

There is only one option: create a new one. The starting point is a rolled steel blade 55C7 or 60R17, with a resistance of 90 kg per cm2. One of the few companies that we can still turn to is the company Eeltink Veertechniek, from Heemskerks, which has existed for about 120 years. The number of blade sizes available for classics is no longer endless. But the address is worth remembering.

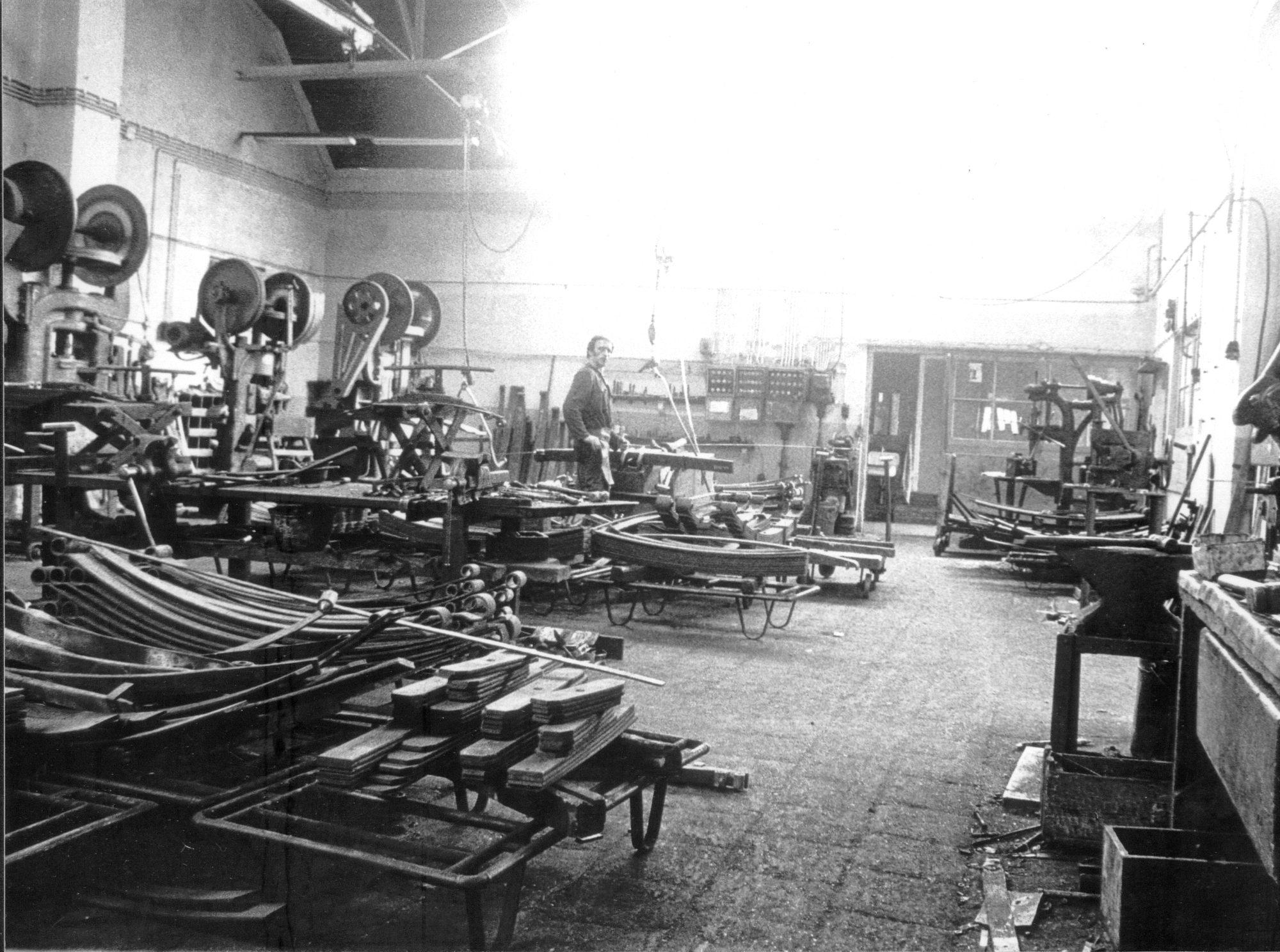

Old and new. Eeltink makes (still) leaf springs

At that tent my brother and I had 30 make new feathers for his A Kadett (also my wedding car) XNUMX years ago.

Car still drives on it. (still in his possession)

If the factory manual says so ... Then the damping of these springs should not be in their own friction. He has just 'modern' rear shock absorbers. They overrule the springs in terms of damping ...

Do not grease leaf springs?

in the factory manual of Triumph/ BL states that you are the transverse leaf spring

of Triumph Herald and Vitesse must regularly in oils.

you get greasy fingers from that.

what is truth now?

anthony.