And then we are not talking about 'plastic is fantastic', like the ABS from Mehari's and so on. But about firmer stuff. Glass fiber reinforced polyester was once seen as 'the new steel'. Glass fiber reinforced polyester is a composite material consisting of a plastic resin matrix, glass fiber reinforcement and some other additives. It provides greater design flexibility that was previously not possible due to the cost of molds and machining during the production of pressed steel parts.

Thermosetting polyester is usually reinforced with glass fiber

This is called glass fiber reinforced polyester, but is often simply referred to as “polyester”. Well-known applications have traditionally been sailing yachts and rowing boats, 'sheet metal' for motorcycles and 'bodywork' for cars. Polyester is a synthetic resin that hardens after adding a hardener. This process is irreversible. Polyester can therefore no longer be melted. Polyester does not rot or rust and can be processed with a minimum of tools.

Processing fiberglass-reinforced polyester can be done in various ways

The most well-known technique is hand laminating. With this technique, unstructured mats or fabrics are impregnated with resin on an open mold. This is done with a brush or roller. All air is then rolled out of the laminate with a vent roller. The desired thickness of the laminate is achieved by the number of layers of glass mat or glass fabric.

Another way to apply the resin is with a sprayer

This method is used when production has to be run. Such a machine has a large and a small pump with which the resin and hardener respectively are pumped to a spray gun. The spray gun has a 'cutter' that chops a continuously supplied glass fiber into small pieces and injects these glass chips with the resin jet. After the glass / polyester mixture has been sprayed onto the mold, it must be deaerated with a vent roller.

With the above techniques, styrene is released during processing. Although this styrene vapor is not immediately a major hazard with adequate ventilation, the penetrating smell can cause nuisance. While there are also people who like the smell.

Polyester is ideal for products where freedom of form is paramount

Polyester with fiberglass is always laminated against a (temporary or temporary) mold. This temporary mold can be made of all kinds of material, and can also become part of the construction. You can make products in a mold, but you can also coat objects. In short, if you can use something to laminate the GVP, it can be made with polyester.

Polyester products can be finished in various ways. Against a smooth mold, gelcoat can be used, an approximately 0,3 mm thick colored layer based on polyester. This layer adopts the surface structure of the mold. A mirror-smooth finish is usually sought. The result may even be that spraying the result in color is not even necessary.

Maybe also interesting: Polyester tubs

Repair with fiberglass-reinforced polyester

Every hardware store sells sets for it: A tin of resin, a tube of hardener and a piece of glass mat. People who just add a good dash of hardener because 'more is always better' can be surprised. The chemical reaction is exothermic. Heat is released during curing. A lot of heat is released when curing very quickly. The result may be that the pot of resin hardens so quickly that the result looks like the sun-dried clay bottom of a dry lake.

Another point of attention: the fiberglass mats consist of ... Glass fibers. When working unprotected, these fibers can be very irritating to the skin. And what do fiber glass particles do in the lungs? Just light a cigarette with that, and we'll talk further.

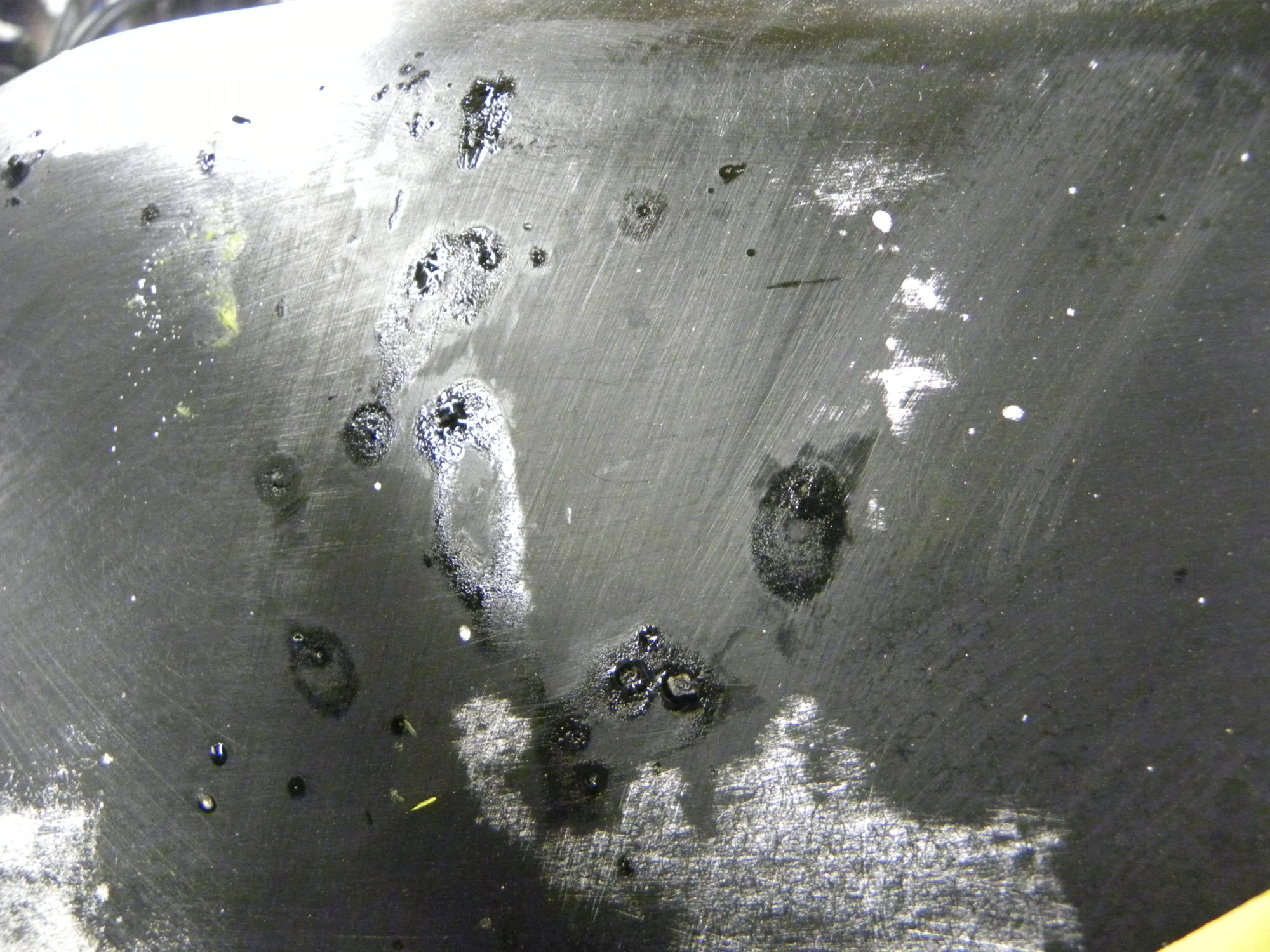

Holes and cracks in polyester are usually easy to repair

- Step 1: Clean the substrate thoroughly and inspect the damage. Thoroughly clean the surface around the damage with, for example, degreaser. Take a good look at how far the crack or hole runs.

- Step 2: Grind / sand sloping edges in the gas or crack. For good adhesion and to ensure that you can rebuild the hole or crack to the correct thickness, it is important to grind the bevel in the crack or hole before you begin the polyester repair. This can easily be done with the fiber disc which you can mount on your grinder. Also sand around the hole for good adhesion for the overlapping fiberglass mats.

- Step 3: Support the substrate if possible. Especially with a larger gap, it is wise to ensure that the surface of the repair is supported. This makes it easier to do the polyester repair properly, because you can rebuild the entire fiber layer. You can do this with, for example, a piece of cardboard and by tightening a piece of string you ensure that it stays in place. You can also do it by applying a little polyester filler with hardener to the edges of the cardboard plate. Then it also sticks well.

- Step 4: Laminating glass mat with polyester. Degrease the substrate around the repair and then we can start rebuilding the fiberglass laminate. Mix the polyester resin with approximately 2% hardener and mix it well. Then apply a little polyester resin with a brush or a brush brush around the repair and possibly on the piece of cardboard. Tear the fiberglass mats into small pieces. Work from small to large. Place a mat on the hole and wet it well with polyester resin. Then you put another piece of fiberglass mat on it which is slightly larger and you make it wet again. Repeat this until you are at the original thickness and have an overlap with the substrate around the crack or hole.

- Step 5: Finishing and continuation. Allow to cure for at least 24 hours and remove the support. After this it can be sanded with a coarse grain and further finished. This can, for example, be done with a polyester topcoat or by first priming and then painting with DD lacquer.

More practical and technical articles

Po ne mbulesat me poliester (ondoluks etalbon)

Indeed Corvettes are made of fiberglass-reinforced polyester. In France they were busy with it in the 50s and 60s: CG, Alpine, etc., 70s: Renault Roedeos, Matra Bagheera, Murena rtc.

The well-known Trabant was also made from a kind of polyester but then reinforced with cotton fibers.

Rodeos

Well the case is that I don't smoke and don't want to smoke. Are you saying it's very flammable?